Why & How

Our bikes have been created to fulfil multiple roles so depending on your style of cycling, you could use our hardtail mountain bike to travel into the wilds of the backcountry fully loaded with luggage and tent and then make camp before riding some single track in the wilderness without your luggage, or enter a local XC mountain bike race when you get home. Or you could use our adventure gravel bike to ride some big routes in the Himalayas fully loaded and once back home use the same bike to commute to work.

Due to this we wanted our bikes to be hardy and fully recyclable so we have chosen to fabricate frames in titanium and spec them with the best the business has to offer.

We are partnered with and contribute monthly to several projects through Earthly who help companies invest in nature through high quality nature-based solutions that remove carbon, restore biodiversity and improve livelihoods. This helps to offset the manufacturing and shipping involved in the fabrication of our bikes and the annual travel of our team.

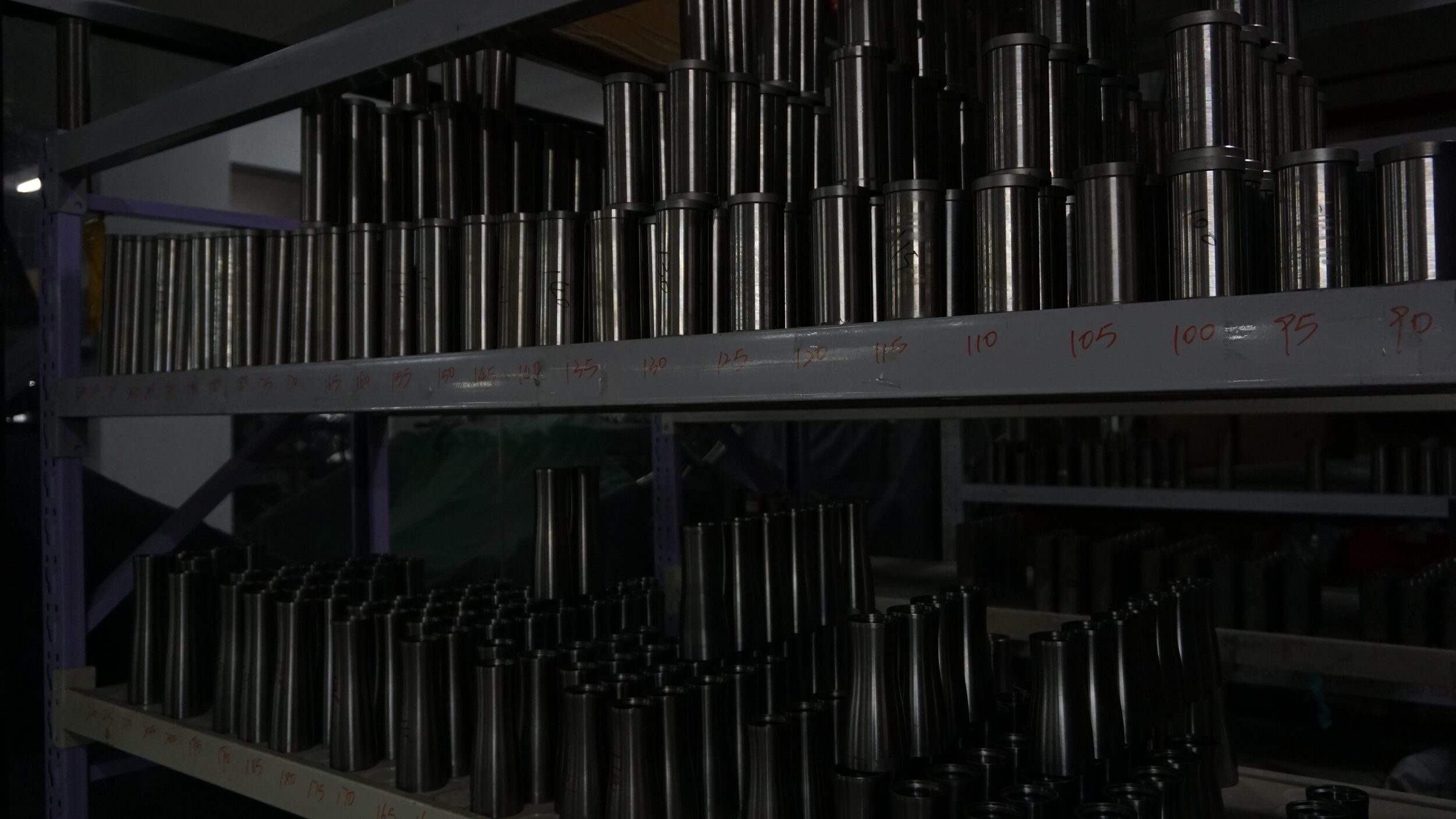

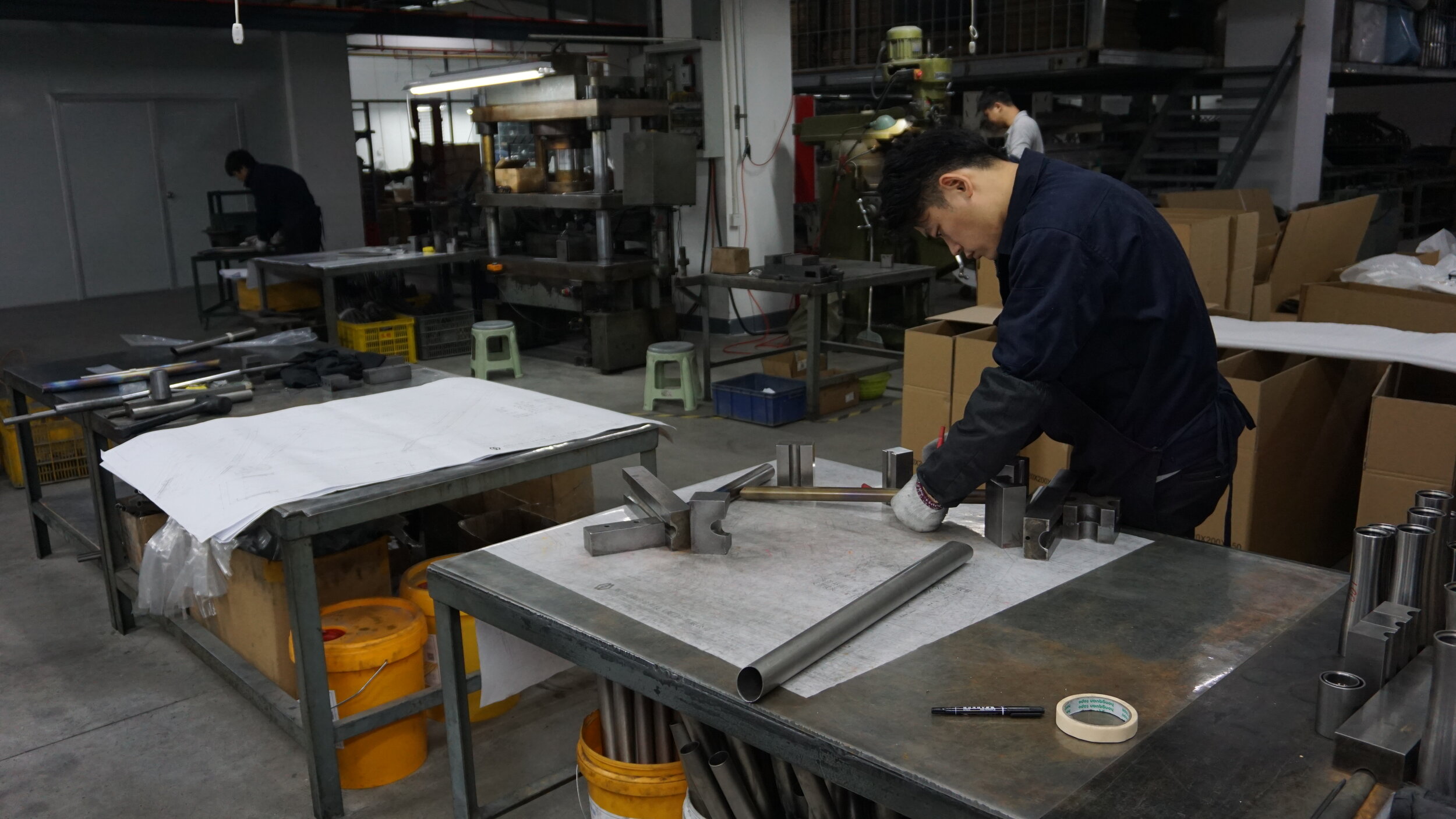

The factory we use to carry out fabrication is in China. They are highly experienced in titanium bicycle manufacturing with 20 years in the industry, ISO 9001 certification and big brands behind them. Aviation grade 3Al-2.5V tubing is used in all our frame production.

Design & build is taken care of inhouse by the Greenrock team in Europe .